Hi readers!

Today lets talk about some other subject we learn

at NITIE. In the last week, I presented on Flexible Manufacturing System in

Industrial Engineering & Productivity Management class. Prof. Narayana Rao

is our faculty for IEPM & I am extremely thankful to him for providing me

such a great opportunity to present above mentioned topic in front of the class

in this digital era.

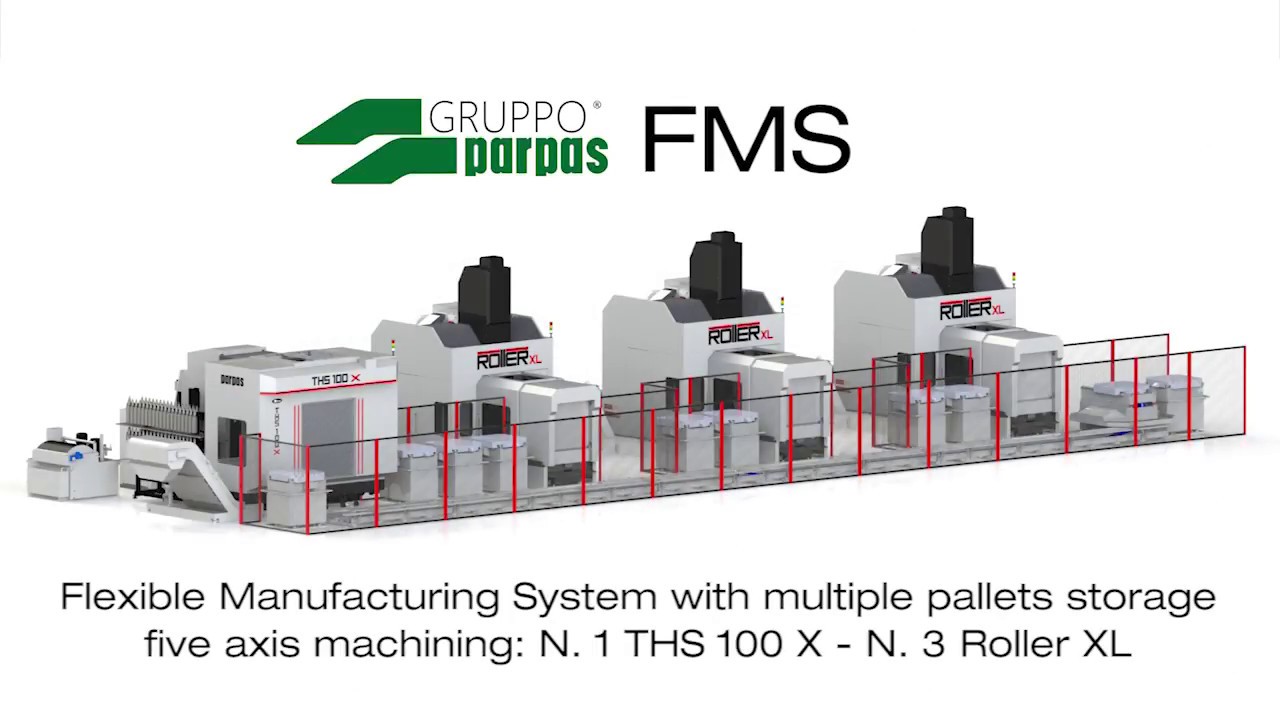

Let's start with the definition of Flexible

Manufacturing System (FMS)

A flexible manufacturing system (FMS) is the production method that is designed to easily adapt to changes in the type and

quantity of the product being manufactured. Machines and computerized systems

can be configured to manufacture a variety of parts and handle changing levels

of production.

The concept of flexible manufacturing was developed

by Jerome H. Lemelson (1923-97), an American industrial engineer and the inventor who filed a number of related patents in the early 1950s. His original

design was a robot-based system that could weld, rivet, convey, and inspect

manufactured goods.

Working Principle:

A flexible manufacturing system may include a

configuration of interconnected processing workstations with computer terminals

that process the end-to-end creation of a product, from loading/unloading

functions to machining and assembly to storing to quality testing and data

processing. The system can be programmed to run a batch of one set of products

in a particular quantity and then automatically switch over to another set of

products in another quantity.

Flexibility Test:

Part variety test: Can

the system process different part styles in a

non-batch mode?

Schedule change test: Can

the system readily accept changes in production schedule and changes in either

part mix or production quantities?

Error recovery test: Can

the system recover gracefully from equipment malfunctions and breakdowns, so

that production is not completely disrupted'!

New part test: Can new part designs be introduced into the existing product mix with relative ease'!.

Types of FMS:

Based on Number of Machines

· Flexible Manufacturing Cell (2-3)

· Flexible Manufacturing System (4 or More)

Based on Level of Flexibility

· Random-order FMS (More Flexible & Lower production rate)

Based on Kinds of Operations Performed

· Assembly Operation

Advantages:

· Lower cost per unit produced

· Greater labour productivity

· Greater machine efficiency

· Improved quality

Challenges in Implementation:

· Substantial pre-planning

· Requirement of skilled labour

· Complicated system

· Maintenance is complicated

This is just a brief about FMS, its advantages and challenges in application.

Stay tuned for more updates!!

Good read👍

ReplyDeleteGood structure and even better content

ReplyDeleteNicely articulated

ReplyDeleteVery insightful

ReplyDeleteHelpful.

ReplyDeleteVery informative

ReplyDeleteThey you for coming up with such an important information. Keep up the good work!

ReplyDeleteVery helpful.

ReplyDeleteA good read! Keep writing such things!

ReplyDeleteWell Written!!

ReplyDeleteNicely presented

ReplyDeleteKaafi sahi

ReplyDeleteSuperb.

ReplyDelete